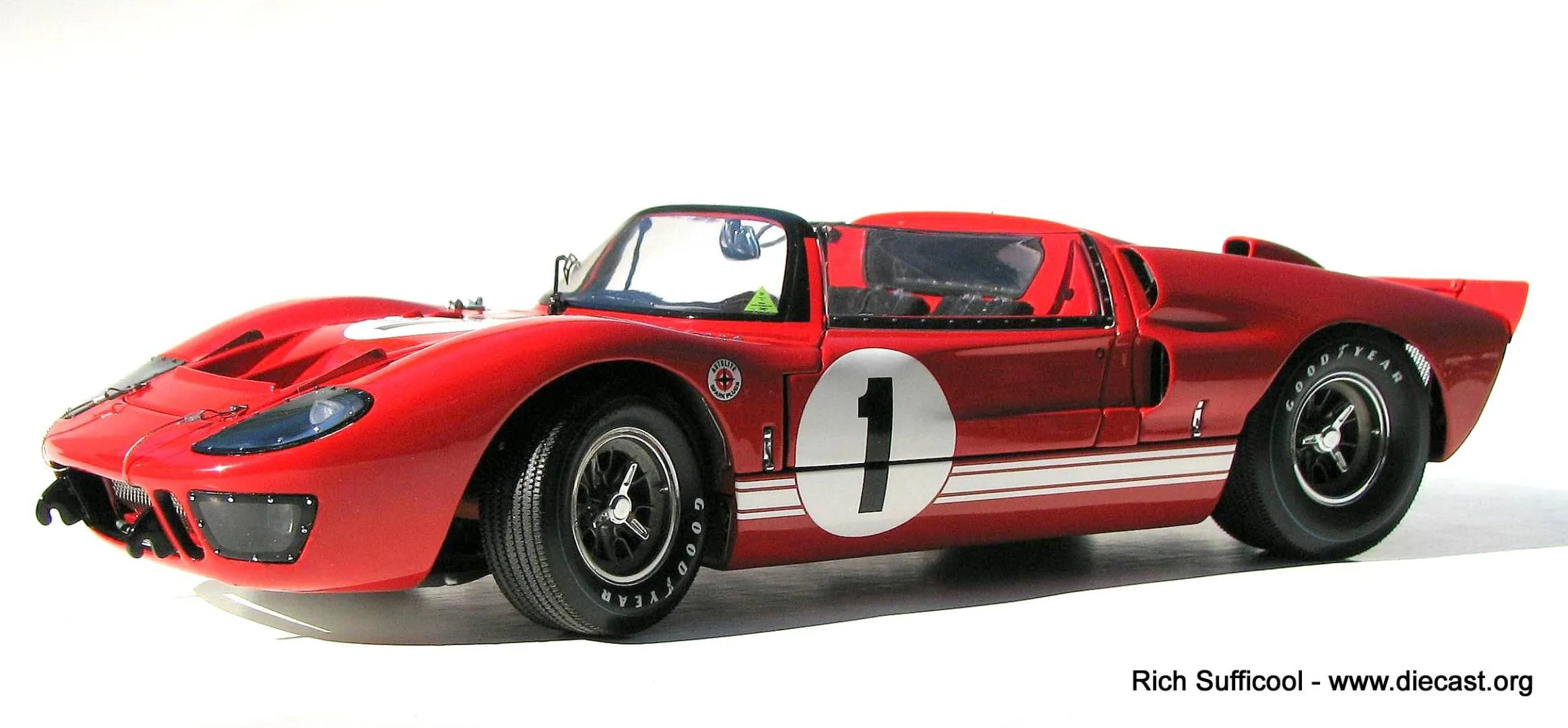

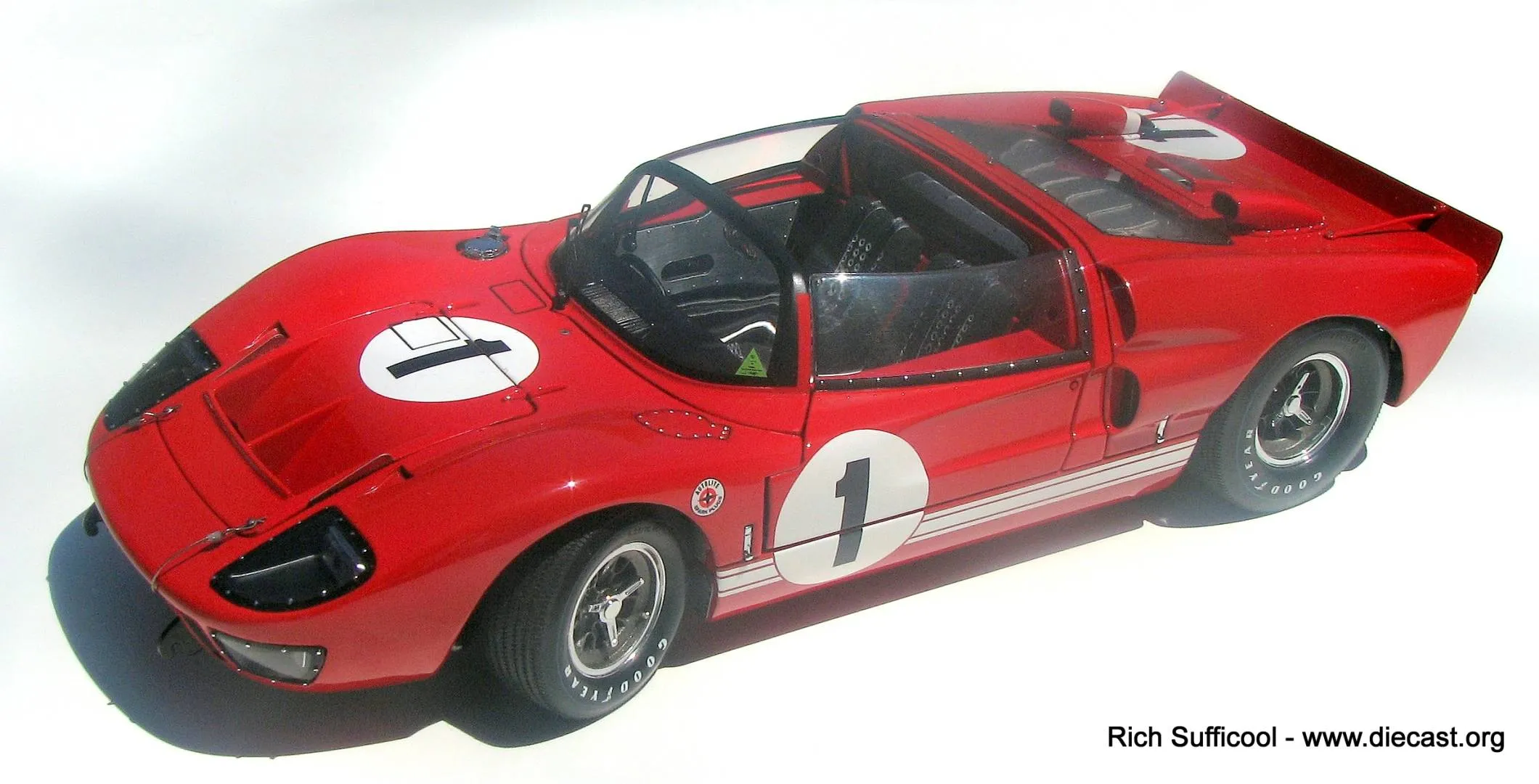

Why Your Ford GT40 Diecast Is Not Working

Owning a Ford GT40 diecast model is a joy, a miniature replica of a legendary race car. However, the experience can quickly sour when your prized possession stops functioning. Whether it’s a mechanical issue, an electrical fault, or a simple oversight, a non-working GT40 diecast can be frustrating. This guide provides a comprehensive, step-by-step approach to diagnose and fix the common problems that plague these miniature marvels. We will explore the likely causes, from simple fixes like replacing batteries to more complex solutions involving disassembly and component replacement. With patience and the right approach, you can restore your GT40 diecast to its former glory.

Common Issues with Diecast Models

Diecast models, despite their robust appearance, are susceptible to a variety of issues. These problems can stem from manufacturing defects, wear and tear, or improper handling. Understanding these common issues is the first step in effective troubleshooting. Regular maintenance, such as cleaning and lubrication, can significantly extend the lifespan of your diecast model. When a problem arises, a systematic approach is crucial. Start by identifying the symptoms—what exactly is not working? Is the model unresponsive, or are specific features malfunctioning? This initial assessment will help narrow down the possible causes and guide you toward the appropriate solution.

Mechanical Problems

Mechanical problems often involve moving parts like wheels, steering mechanisms, and opening doors or hoods. Over time, these parts can become stiff, misaligned, or damaged. Dust and debris can accumulate, hindering movement and causing friction. Lubrication is key in preventing these issues. Applying a small amount of lubricant to moving parts can ensure smooth operation. Avoid using excessive amounts of lubricant, as this can attract more dust and potentially damage the model’s paint. Regular inspection of these mechanical components is essential to identify any issues early on. Addressing these problems promptly can prevent further damage and keep your diecast model in optimal condition.

Battery Issues

Battery-powered diecast models are prone to battery-related issues. The most common problem is a dead or depleted battery. Corrosion can also occur if batteries are left in the model for extended periods, especially if the model is not in use. This corrosion can damage the battery compartment and affect electrical connections. Regularly checking the batteries and replacing them when necessary is crucial. Always use the correct type of batteries recommended by the manufacturer. If corrosion is present, clean the battery compartment with a specialized cleaner or a mixture of baking soda and water, ensuring all residue is removed before inserting new batteries. Proper battery maintenance is often the most straightforward fix for many diecast model problems.

Electrical Faults

Electrical faults can be more challenging to diagnose. These issues can range from loose wiring to motor failures. The wiring within a diecast model is often delicate, and can be damaged by rough handling or aging. Motors can wear out over time, ceasing to function. Start by inspecting the wiring for any breaks or loose connections. Use a multimeter to test the continuity of the circuits, ensuring that electricity is flowing correctly. If you suspect a motor failure, you may need to replace the motor, which typically requires some disassembly. Soldering skills may be needed. Addressing electrical faults can restore functionality and extend the life of your diecast model.

Step 1 Checking the Basics

Before diving into complex repairs, start with the basics. Often, the simplest solutions are the most effective. These initial checks can save you time and effort, and prevent unnecessary disassembly. A quick and easy check can often identify the root cause of the issue. Take a moment to review the model’s condition and any obvious signs of problems. This proactive approach can often resolve issues quickly.

Visual Inspection

A visual inspection is the first step in troubleshooting. Look for any obvious signs of damage, such as broken parts, loose components, or signs of corrosion. Check the wheels for any obstructions or misalignment. Examine the body for any dents or damage that might be interfering with the moving parts. Also, look closely at the battery compartment for any signs of leakage or corrosion. A thorough visual inspection can often reveal the source of the problem without any further testing. Document any findings with photos and notes, as this information will be valuable as you proceed with the repair.

Battery Check

If your diecast model is battery-powered, the first thing to check is the batteries. Ensure that the batteries are inserted correctly and that they have not expired. Use a multimeter to test the voltage of the batteries. Replace the batteries with fresh ones if they are dead or weak. Clean any corrosion from the battery contacts with a cotton swab and a cleaning solution. Be sure to use the correct battery type and follow the manufacturer’s instructions. A simple battery replacement can resolve many common issues. Confirm the model’s functionality after replacing the batteries.

Step 2 Assessing Mechanical Components

Once you’ve checked the basics, the next step is to examine the mechanical components. These parts are prone to wear and tear. Inspecting these components can help identify problems with wheel movement, steering mechanisms, and other moving parts. Pay careful attention to how each part functions and if any issues are present. Addressing mechanical problems promptly can prevent further damage.

Wheel and Axle Issues

Wheels are critical for the model’s movement, and any issues can cause malfunction. Check if the wheels spin freely, or if they are blocked or stiff. Inspect the axles for any damage or bending. Remove any obstructions such as dust or debris that might be hindering wheel movement. Lubricate the axles and wheel connections with a suitable lubricant. Ensure all wheels are properly aligned and that they make contact with the surface. A little maintenance and checking can often resolve wheel and axle problems.

Steering Mechanism Problems

If your model has a steering function, inspect the steering mechanism. Check for any obstructions or stiffness in the steering linkage. Make sure the steering wheel and wheels are properly connected and functioning correctly. Examine the gears or mechanisms for any damage or wear. Lubricate the steering components to ensure smooth movement. If the steering is unresponsive, you may need to adjust or replace certain parts. The steering system’s smooth operation will enhance the model’s overall functionality.

Step 3 Examining Electrical Systems

If your diecast model uses electrical components, such as lights or a motor, it’s essential to check the electrical systems. These systems can be complex, so proceed carefully. Inspecting the wiring, testing the motor, and checking for any shorts or breaks will ensure your model’s electrical components work efficiently. Proper electrical maintenance is essential for restoring function and enhancing the model’s operation.

Wiring Inspection

Inspect the wiring for any breaks, loose connections, or frayed wires. Use a magnifying glass to check for small faults. Gently tug on the wires to ensure they are securely connected to the components. If you find any broken wires, you’ll need to carefully solder them back together. If the wires are frayed, consider replacing them. Use electrical tape or heat shrink tubing to insulate the repaired wires. Ensure all connections are secure and well-insulated to prevent shorts. Taking the time to properly inspect and repair the wiring is a critical step in restoring function.

Motor Functionality Test

If your diecast model has an electric motor, you’ll need to test its functionality. First, ensure the motor is receiving power. If the motor has a separate power source, verify the batteries are functional. If the motor is connected to the model’s main power source, check that the power is reaching the motor terminals. Use a multimeter to test the motor’s continuity. If the motor is not working, it may need to be replaced. Replacement often involves removing the existing motor and installing a new one. Following the manufacturer’s specifications and using the correct replacement motor will ensure proper function. Motor function is often essential to the functionality of many diecast models.

Step 4 Advanced Troubleshooting Techniques

If the initial steps don’t resolve the issue, it’s time for more advanced troubleshooting techniques. Disassembly and component replacement may be necessary. These techniques require precision, patience, and the right tools. Carefully documenting each step can prove useful if the need to return the model to its original state arises. Proceeding slowly and methodically will minimize the risk of causing further damage and increase the chances of success.

Disassembly and Reassembly

Disassembly should only be performed if you have experience and the necessary tools. Begin by carefully documenting the model’s original condition with photos. Remove any screws or fasteners, and carefully separate the components. Organize the parts systematically to facilitate reassembly. Use the proper tools, such as small screwdrivers, tweezers, and pliers. During reassembly, ensure all parts are correctly aligned and that no components are missing. Refer to your photos and notes to help you reassemble the model correctly. Reassembly can be a rewarding process if done systematically.

Component Replacement

If a component is damaged, replacement may be necessary. Identify the specific part that needs replacement. Source the correct replacement part from a reputable supplier. Before removing the damaged part, take note of its placement and connections. Use the correct tools to remove the damaged component. Install the new part, ensuring it is correctly aligned and secured. Test the model’s function to confirm the repair. Component replacement can restore the function of your model and keep it in excellent shape.

Step 5 Seeking Professional Help

If you’ve exhausted all the troubleshooting steps and the model still isn’t working, it’s time to seek professional help. Attempting a repair beyond your skill level can lead to further damage. Consulting an expert diecast model repair service is the next step. A professional will have the necessary skills, tools, and experience to properly diagnose and repair the issue.

When to Consult an Expert

If you are uncomfortable with disassembly, have limited experience with electronics or mechanics, or if the repair is beyond your skill level, it’s best to seek professional help. If the model is valuable or rare, it’s also wise to consult an expert. Professionals have the experience and tools to repair intricate issues. A professional repair will help protect your investment. Identifying when you need help is important for preserving your diecast model.

Finding a Repair Service

Finding a reputable repair service can be a little difficult, but the internet is a great resource. Search online for diecast model repair services in your area. Check online reviews and testimonials to ensure the service has a good reputation. Ask for referrals from model car clubs or communities. When choosing a repair service, ensure they have experience repairing the specific type of model you own. Inquire about their pricing and turnaround time. Having your model repaired by a professional can restore its functionality. Trusting your model to the right hands will ensure that your diecast model is in the best possible condition.

In conclusion, fixing a non-working Ford GT40 diecast model can be achieved by systematically following the outlined steps. From basic checks to more advanced techniques, this guide covers all the essential aspects of troubleshooting and repair. Remember to start with the basics, inspect components carefully, and proceed with caution. With patience and the right approach, you can restore your GT40 diecast model and enjoy its beauty for years to come.