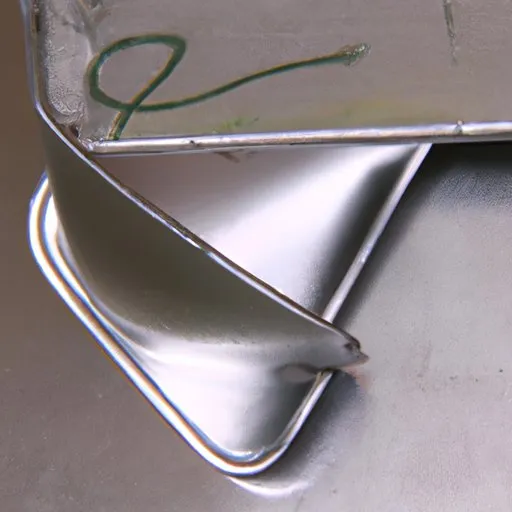

What is Diecast Metal?

Diecast metal refers to metal components manufactured through a high-pressure die casting process. This method involves injecting molten metal, typically alloys like aluminum, zinc, or magnesium, into a mold (die) under immense pressure. The rapid cooling and solidification within the die result in intricate and precise shapes, making die casting an ideal process for mass production of complex parts. The resulting components are widely used across various industries, from automotive and aerospace to consumer electronics and toys, thanks to their dimensional accuracy, surface finish, and mechanical properties. Understanding the nature of diecast metal is crucial before considering any welding attempts.

Composition of Diecast Metals

The composition of diecast metals significantly influences their weldability. These metals are not pure but are alloys, meaning they are mixtures of different metals and elements designed to achieve specific properties. The specific composition affects the melting point, thermal conductivity, and the formation of oxides during welding. The presence of certain elements can lead to difficulties such as increased porosity or the formation of brittle intermetallic compounds. Furthermore, the composition varies depending on the application and desired properties, which requires a careful assessment to determine the most appropriate welding method.

Common Diecast Metals

Several metals are commonly used in die casting, with aluminum, zinc, and magnesium being the most prevalent. Aluminum die castings are valued for their lightweight, high strength-to-weight ratio, and excellent corrosion resistance, making them popular in automotive and aerospace applications. Zinc die castings are known for their good dimensional stability, ability to produce thin-walled parts, and excellent finishing characteristics; they are often found in hardware and consumer goods. Magnesium die castings, known for being the lightest structural metal, are used in applications where weight reduction is critical, such as portable electronics. The weldability of each of these materials differs, so the choice of welding process needs to consider the specific alloy involved.

Can You Weld Diecast Metal?

The question of whether you can weld diecast metal is complex. It is technically possible to weld certain diecast metals, but it is often challenging and may not always be the best solution. The process is complicated by the composition of diecast metals, which includes alloys designed for casting rather than welding. These alloys can present issues like porosity, oxide formation, and varying melting points. Proper preparation, the correct welding method, and specific parameters are essential to achieving a successful weld. Due to these challenges, welding diecast metal is often considered a last resort, and alternative joining methods are preferred when feasible. The success of the weld also depends greatly on the skill of the welder and the specific application.

Challenges of Welding Diecast Metals

Several challenges arise when welding diecast metals that require careful consideration. These challenges can lead to weak welds, aesthetic issues, or even render the part unusable. Understanding these hurdles is vital for anyone considering welding diecast metal. Some of the most significant challenges include porosity, the formation of oxides, and alloy composition.

Porosity

Porosity is one of the most common issues encountered when welding diecast metals. It refers to the presence of voids or small holes within the weld. Porosity occurs because gases trapped within the molten metal during welding cannot escape before the metal solidifies. The high gas content, often from impurities or the alloy composition, combined with the rapid cooling rates characteristic of welding, contributes to this problem. Porosity weakens the weld, reducing its strength and making it prone to cracking. Controlling porosity requires careful welding techniques, including the use of appropriate shielding gases and precise welding parameters.

Oxide Formation

Oxide formation is another significant challenge. Diecast metals, particularly aluminum and magnesium alloys, readily react with oxygen in the air to form surface oxides. These oxides have higher melting points than the base metal, hindering the weld’s fusion and leading to defects like lack of fusion or inclusions. Removing or minimizing oxide formation is essential for achieving a sound weld. This often involves meticulous surface preparation, using inert shielding gases, and selecting the correct welding parameters. Effective oxide removal ensures proper metal-to-metal contact and the creation of a strong, durable weld.

Alloy Composition

The specific alloy composition of the diecast metal significantly impacts weldability. The presence and proportion of alloying elements such as silicon, copper, and zinc influence the metal’s melting point, thermal conductivity, and susceptibility to cracking. Some elements, like silicon, can improve weldability, while others, like zinc, can create porosity or other defects. The welder must understand the alloy composition to select the appropriate welding process, filler metal, and parameters. Consulting the material’s specifications or conducting preliminary testing may be necessary to achieve optimal results.

Welding Methods for Diecast Metal

Several welding methods can be employed when working with diecast metals, each with its advantages and limitations. The choice of method depends on the specific metal, the desired weld quality, and the available equipment. TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and soldering are common approaches. Careful consideration of each method’s characteristics and requirements is essential to choose the most appropriate one for the job.

TIG Welding

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a versatile process suitable for welding diecast metals. TIG welding uses a non-consumable tungsten electrode to create the weld. An inert gas, usually argon, shields the weld area from atmospheric contamination. The welder controls the heat input with a foot pedal, allowing for precise control over the welding process. TIG welding produces high-quality welds with good control over the weld bead, which makes it an excellent choice for thinner diecast metal parts or where aesthetics are important. However, TIG welding requires skilled operators and is generally a slower process than MIG welding.

MIG Welding

MIG welding, or Gas Metal Arc Welding (GMAW), is another method that can be used on diecast metals. It uses a continuous wire electrode that melts into the weld pool. An inert gas, such as argon or a mixture of argon and helium, shields the weld area. MIG welding is faster than TIG welding, making it suitable for thicker sections or high-volume applications. However, MIG welding may produce a weld with less precision and may be more prone to porosity if the parameters are not carefully controlled. The choice between TIG and MIG often depends on the specific application and the welder’s preference.

Soldering

Soldering is a lower-temperature joining process that can be an alternative to welding diecast metals, especially for thinner sections or when a strong weld is not critical. Soldering involves melting a filler metal with a lower melting point than the base metal, creating a bond between the parts. Soldering is less prone to the challenges associated with welding, such as porosity and high-temperature distortion. However, soldered joints are generally weaker than welded joints and may not be suitable for high-stress applications. Soldering requires careful surface preparation and the use of appropriate fluxes to ensure a good bond. This method is useful for joining diecast metals when the welding process is not feasible or desirable.

Best Practices for Welding Diecast Metal

Successful welding of diecast metal requires strict adherence to best practices. These practices focus on preparing the material, selecting suitable welding parameters, and providing appropriate post-weld treatment. By following these guidelines, welders can improve the chances of producing sound, reliable welds. Ignoring these practices may lead to weld failures or compromise the integrity of the components.

Surface Preparation

Proper surface preparation is crucial for welding diecast metal. This process removes contaminants, oxides, and any coatings that can interfere with the welding process. Start by thoroughly cleaning the surface with a degreaser to remove oils, grease, and other contaminants. Next, use a stainless steel brush or abrasive to remove any oxides. For aluminum and magnesium alloys, it may be beneficial to use a chemical etching process. The cleaner and more prepared the surface, the better the weld quality. Skipping this step can lead to porosity, lack of fusion, and weak welds. Proper preparation significantly increases the likelihood of a successful welding outcome.

Welding Parameters

Choosing the right welding parameters is critical for achieving a high-quality weld on diecast metal. Parameters such as current, voltage, travel speed, and shielding gas flow rate must be set appropriately to prevent defects. Start with the manufacturer’s recommendations for the specific alloy and thickness of the material. Use the lowest possible heat input to minimize the risk of distortion and porosity. The correct choice of filler metal is equally important. Use filler metals that are compatible with the base metal. Precise control over these parameters is a key element in minimizing weld defects and ensuring the weld’s strength and integrity.

Post-Weld Treatment

Post-weld treatment can improve the properties of the weld and the surrounding material. Depending on the alloy and the application, post-weld treatments may include stress relieving, heat treating, or surface finishing. Stress relieving can reduce residual stresses in the weld, which can prevent cracking. Heat treating can improve the mechanical properties of the welded joint. Surface finishing, such as machining or polishing, can improve the appearance and corrosion resistance of the weld. Implementing these post-weld treatments helps optimize the performance and longevity of the welded component. Consideration of these treatments can contribute significantly to the overall quality and reliability of the final product.

Alternatives to Welding Diecast Metal

Due to the challenges associated with welding diecast metal, alternative joining methods are frequently preferred. These alternatives often provide a simpler, more reliable, and more cost-effective solution. The choice of alternative depends on the specific application, the required strength, and the desired appearance. Mechanical fastening and adhesive bonding are two commonly used alternatives.

Mechanical Fastening

Mechanical fastening involves using screws, bolts, rivets, or other fasteners to join diecast metal components. This method is a reliable way to create strong joints. Mechanical fastening is a relatively straightforward process and does not require specialized equipment or extensive training. It is especially suitable for applications where disassembly is required. Proper design and selection of fasteners are critical to ensure the joint’s strength and durability. Mechanical fastening is a versatile and cost-effective option for many applications and is often preferred over welding when feasible.

Adhesive Bonding

Adhesive bonding uses strong adhesives to join diecast metal components. This method can create a strong and durable bond. The adhesive distributes the stress over a larger area, which reduces stress concentrations. Modern adhesives have excellent bonding characteristics and can withstand various environmental conditions. Adhesive bonding is suitable for applications where a smooth, seamless joint is desired. The surface must be properly prepared to ensure a good bond. This method is a practical and aesthetically pleasing alternative to welding for diecast metal applications.

Conclusion

In conclusion, welding diecast metal is a complex task that requires careful consideration of various factors. While it is technically possible to weld diecast metals, the process presents challenges such as porosity, oxide formation, and alloy composition issues. TIG welding, MIG welding, and soldering are possible welding methods, but they require skilled operators, meticulous surface preparation, and precise control over welding parameters. Mechanical fastening and adhesive bonding often provide more straightforward and reliable alternatives. Ultimately, the decision of whether to weld diecast metal should be based on a thorough assessment of the application’s requirements, the available resources, and the desired outcome. When welding is necessary, a deep understanding of best practices and the use of appropriate techniques can significantly increase the chances of success.